Introduction of Support Project

- What We Do

- Current locationIntroduction of Support Project

What is a smart factory?

Definition

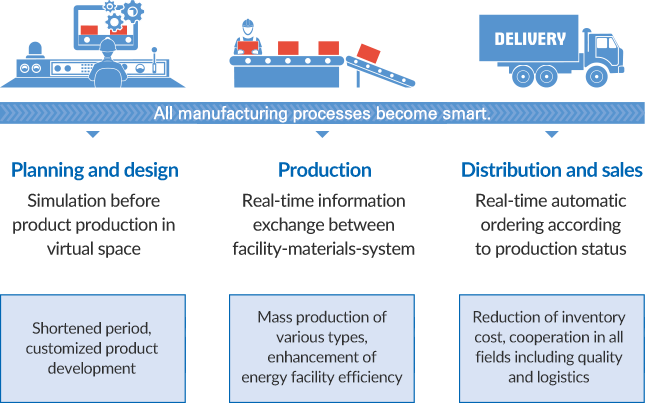

A smart factory is a people-oriented high-tech intelligent factory that integrates all production processes from product planning to sales with ICT (Information and Communication) technology to produce customized products at minimum cost and time.

Scope

Is it a 'smart factory' just because the process of manufacturing products has been changed? The answer is no.

A smart factory relates to all processes related to manufacturing, from product planning and development to mass production, and from order to shipment of finished products.

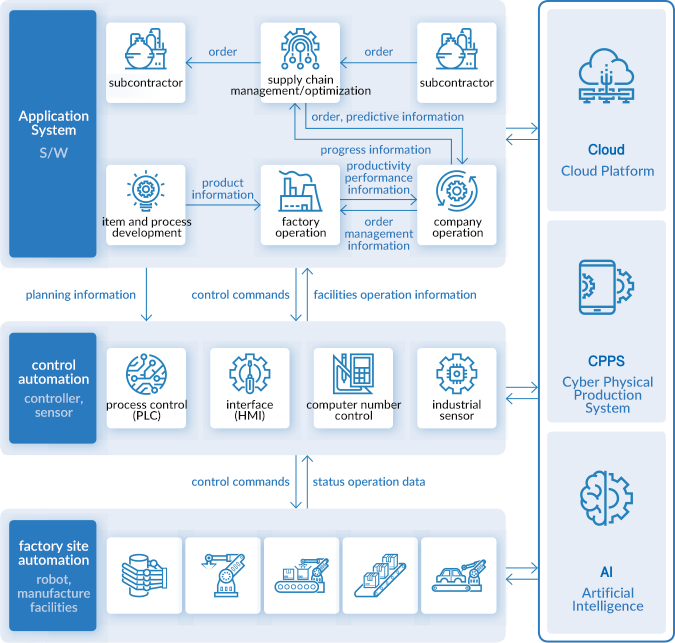

It covers all aspects of factory operation, not only from the application system but also the field automation and control automation areas.

Smart factory seen by stage

The existing smart factories have been classified into ‘Not Introduced – Basic - Medium 1- Medium 2 – Advanced’ depending on the degree of use and capacity of ICT technology.

From this year, the Basic level has been divided into two levels consisting of Level 1 - Level 5.

The companies considering the introduction of a smart factory do not have to worry about Level 5 and upgrade from the first stage.

As a smart factory can be implemented gradually depending on the company's capacity or situation, it is important to select and concentrate on the appropriate level and capacity according to the circumstances of the company.

At present, many small and medium-sized enterprises (SMEs) are starting a smart factory at the basic levels (Level 1, Level 2), which can be easily started at a relatively low cost, and are satisfied with the performance exceeding expectations.

Even at a basic level, the companies can directly compile and manage the products in real time, and even manage material history (lot-tracking).

This must be a big difference before and after the introduction of a smart factory.

It is possible to build a smart factory in stages that is suitable for the company.

| Level Definition |

Standard | IOT Object | Features | Conditions (Level of construction) |

Main tools | |

|---|---|---|---|---|---|---|

| Advanced | Level5 | Autonomous operation | Workers, facilities, materials, operating conditions + environment | Customized | Autonomous progress from monitoring to control and optimization | AR/VR,CPS |

| Medium 2 | Level4 | Optimization | Workers, facilities, materials, operating conditions + environment | Optimized | Possible to respond in advance through process operation simulation | Sensor controller optimization tool |

| Medium 1 | Level3 | Control | Workers, facilities, materials | Analysed | Control by analyzing collected information | Sensor+ analytical tool |

| Basic | Level2 | Monitoring | Workers, facilities, materials | Measured | Monitoring of production information is possible in real time | Sensor |

| Level1 | Check | environment | Identified | Partial standardization and data management | Barcode RFID |

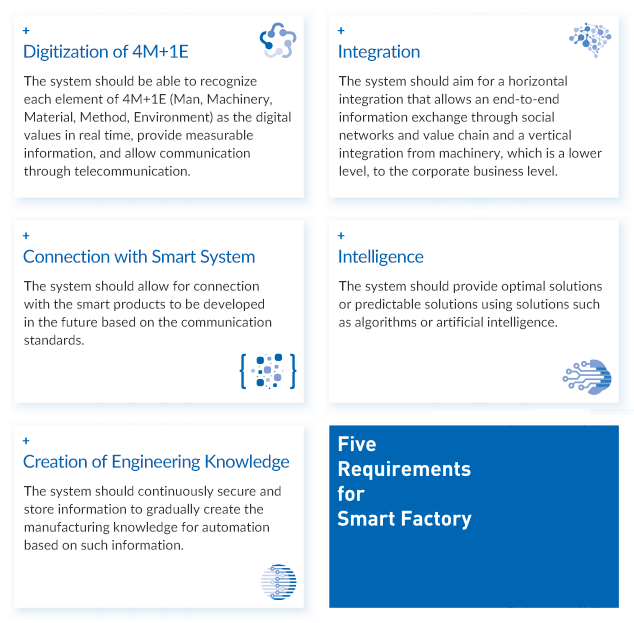

Five Major Requirements

Below are five essential conditions in constructing a smart factory and developing it by level.